Article

Beckman microscopist T. Josek stands next to the new Zeiss Xradia 630 Versa micro-CT scanner, which is located in the institute's Microscopy Suite. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

Beckman microscopist T. Josek stands next to the new Zeiss Xradia 630 Versa micro-CT scanner, which is located in the institute's Microscopy Suite. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

In conversation, a scintillating idea excites your discussion partners and transforms them into more inspired, illuminated versions of themselves. In physics, a scintillating material excites X-rays, transforming them into visible light. Micro-CT scanners, better known as X-ray microscopes, make use of both meanings.

The Beckman Institute for Advanced Science and Technology recently added a new X-ray microscope to its Microscopy Suite. The Zeiss Xradia 630 Versa micro-CT scanner is available to University of Illinois Urbana-Champaign investigators and may be used to support research projects around the world.

Want a slice?

Computed tomography, abbreviated to CT, is an imaging technique not unlike a sandwich. Tomography, or “imaging with slices,” means capturing a series of cross-sectional X-ray scans (the slices) of an object — be it a vegetable, a mineral or even a person. Piled on top of one another like lettuce, turkey and Swiss, the images reconstruct the subject in 3D from the inside out — without ever making a cut.

According to Mayo Clinic, CT is useful for imaging most areas in the body but is best for “bones, blood vessels and soft tissues” like muscles. Doctors use it to diagnose tumors, spot blood clots and guide biopsies. At the Beckman Institute, interdisciplinary researchers use CT scans to study how our bodies move and heal and work toward preventing injuries like broken bones, torn ligaments and arthritis.

Good energy only

With microscopic computed tomography, also known as micro-CT or X-ray microscopy, researchers apply CT techniques to reconstruct samples as tiny and delicate as collagen and insect antennae. Most micro-CT scanners use only X-rays, which are invisible to the human eye, but Beckman’s new model also incorporates the kind of light we can see.

Josh Gibson. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

“First, X-rays are fired through the object we’re imaging. After the X-rays pass through, a detector picks them up and converts them into visible light. The light allows the microscope to further magnify the image,” said

Josh Gibson, a Beckman microscopist who works with the scanner.

Josh Gibson. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

“First, X-rays are fired through the object we’re imaging. After the X-rays pass through, a detector picks them up and converts them into visible light. The light allows the microscope to further magnify the image,” said

Josh Gibson, a Beckman microscopist who works with the scanner.

Converting high-energy photons like X-rays into visible light is called scintillation, Gibson said, warning that sometimes, lower-energy photons sneak through and muddle the results.

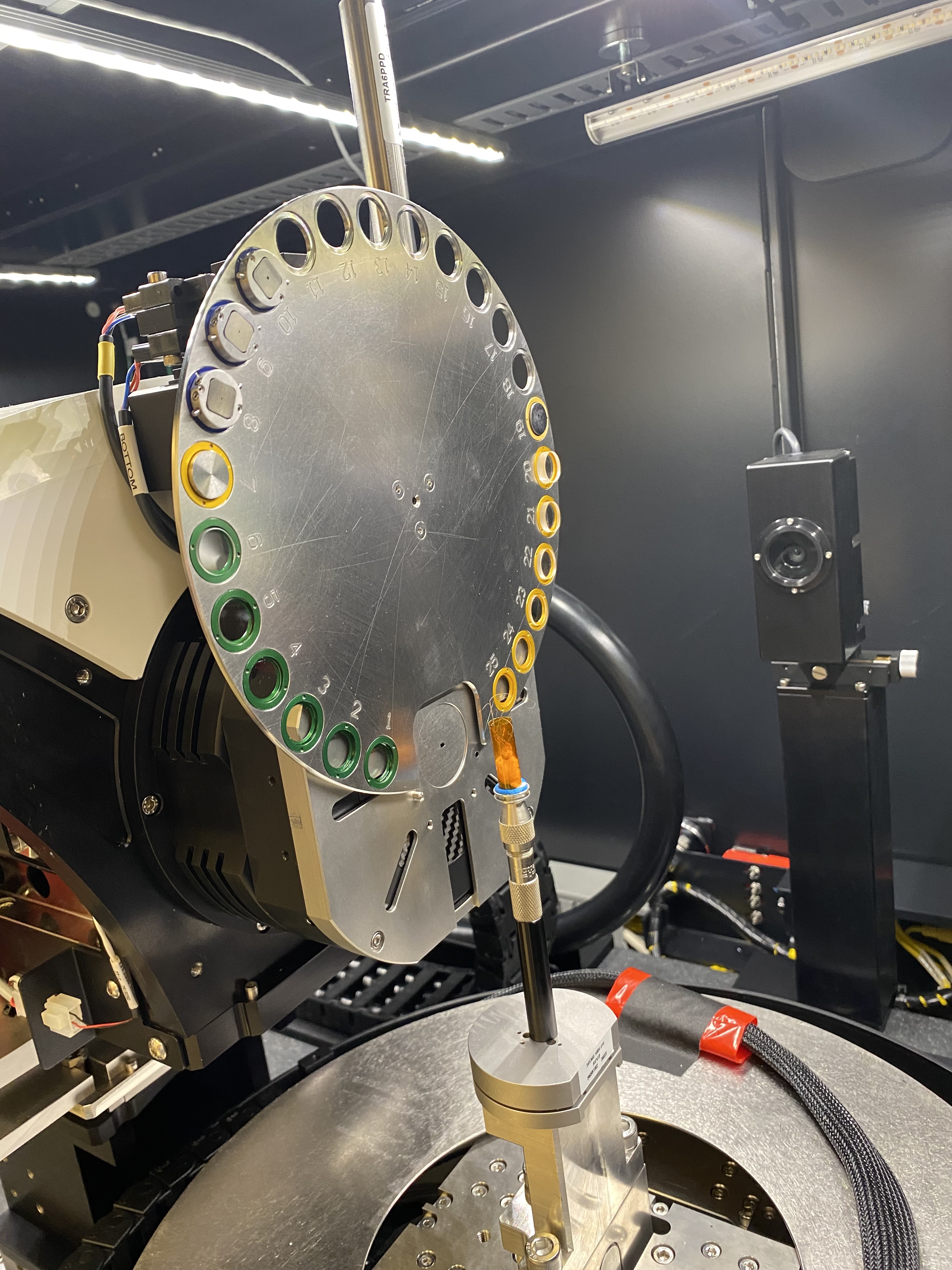

Handily, the Versa is equipped with a Ferris wheel of filters to block unnecessary rays and keep the energy high.

All about angles

A Ferris wheel of filters and rotating scanning stage allow non-destructive virtual reconstruction of specimens as delicate as the daddy longlegs spider pictured. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

X-ray, scintillation, image slice. This rhythm repeats thousands of times as a sample makes a full 360-degree rotation on the scanning stage — like a bizarre paparazzi ambush for a train on its turntable.

A Ferris wheel of filters and rotating scanning stage allow non-destructive virtual reconstruction of specimens as delicate as the daddy longlegs spider pictured. Credit: Jenna Kurtzweil, Beckman Institute Communications Office.

X-ray, scintillation, image slice. This rhythm repeats thousands of times as a sample makes a full 360-degree rotation on the scanning stage — like a bizarre paparazzi ambush for a train on its turntable.

Capturing X-rays from all angles contributes to a complete, spatially accurate 3D reconstruction of each sample — what Gibson gratefully calls “non-destructive virtual dissection,” since it spares such delicate specimens as leafhopper insects and spiders.

Larger samples, though, need more elbow room. That’s why most micro-CT scanners require samples to squeeze into the allotted scanning window — or inch farther away until they fit.

“Imagine using a micro-CT to look at a slab of concrete. With most scanners, you’d need to move the block of concrete far away from the detector to keep the whole thing within that window,” said T. Josek, a Beckman microscopist.

Not so for the Versa 630, which “can take a high-quality scan of just a small subsection — like a crack inside the concrete — instead of scanning the whole thing and zooming in on the cracked area later,” Josek said.

Figuratively, it’s the difference between taking a professional portrait for your resume or zooming in on a grainy group photo. Literally, it may be the difference between a pothole-laden road and a highway built to last.

“There has been a push toward developing more sustainable materials that will last longer. We already know how to make something like concrete cheaply, and easily, but is it the best?” Josek said. “With building materials, hairline cracks are the start of where things go catastrophically wrong, and the micro-CT scanner at the Beckman Institute can see those cracks.”

“We’re providing the opportunity for researchers at the University of Illinois and beyond to start here and start small — see how a material behaves and what it looks like, and then scale up,” Josek said.

Speaking of small: the 630 Versa’s maximum imaging resolution is 40 nanometers, 2,500 times narrower than the width of a human hair.

Bop it, stretch it, scan it

The Versa 630 isn’t just for looking — two standout features allow researchers to get physical with their specimens, too.

Researchers across disciplines can use the compression/tensile stage to stretch, bend and compress their samples while scrutinizing them up close — a technique called in situ mechanical testing.

T. Josek.

“Ceramics people can see how their samples crack under pressure,” Josek said. “Anyone doing anything with asphalt can visualize the impact of cars running over it. People working on self-healing materials can test how their

materials heal after being cracked or stretched.

T. Josek.

“Ceramics people can see how their samples crack under pressure,” Josek said. “Anyone doing anything with asphalt can visualize the impact of cars running over it. People working on self-healing materials can test how their

materials heal after being cracked or stretched.

Mikayla Hoyle, a researcher in the Tissue Biomechanics Lab, will use this function to study how movement and exercise impact bone tissue. By adding weight to a tissue sample — to simulate the pounding of feet on pavement during a jog, for example — she “can analyze deformation to the bone by comparing a before image, when the sample is unloaded, with an after image, when load is applied,” she said, adding that the Versa 630 helps the researchers move beyond the surface of the bone to see what’s happening inside it.

Mikayla Hoyle.Her technique is called digital volume correlation and can provide “insight into what is happening in our bones during different movements, like walking or climbing stairs, and help further identify what characteristics indicate healthy bone,”

Hoyle said.

Mikayla Hoyle.Her technique is called digital volume correlation and can provide “insight into what is happening in our bones during different movements, like walking or climbing stairs, and help further identify what characteristics indicate healthy bone,”

Hoyle said.

The Versa 630 can also do diffraction contrast tomography, a technique usually found adjacent to a particle accelerator wherein researchers can determine grain orientation of a given material, like a metal, by tracking how X-rays bend as they pass through it.

Mixing materials (and people)

Interdisciplinary researchers are already lining up to scan their materials and specimens, Josek said.

“Sometimes, when you get new equipment, the hardest part is getting people to start using it. It’s exciting for us to have a new piece of equipment that just shows up, and immediately there’s a high demand,” they said.

The high demand is due in part to the collaboration that made acquiring the 630 Versa possible.

The scanner was installed in January 2024 and replaces the Microscopy Suite’s Xradia microXCT-400 CT scanner, an older model of the same line that became inoperable in 2023. Seeking a suitable replacement, Beckman microscopists worked with Paul Braun, a Beckman researcher and the director of the Materials Research Laboratory, to consider both institutes’ needs.

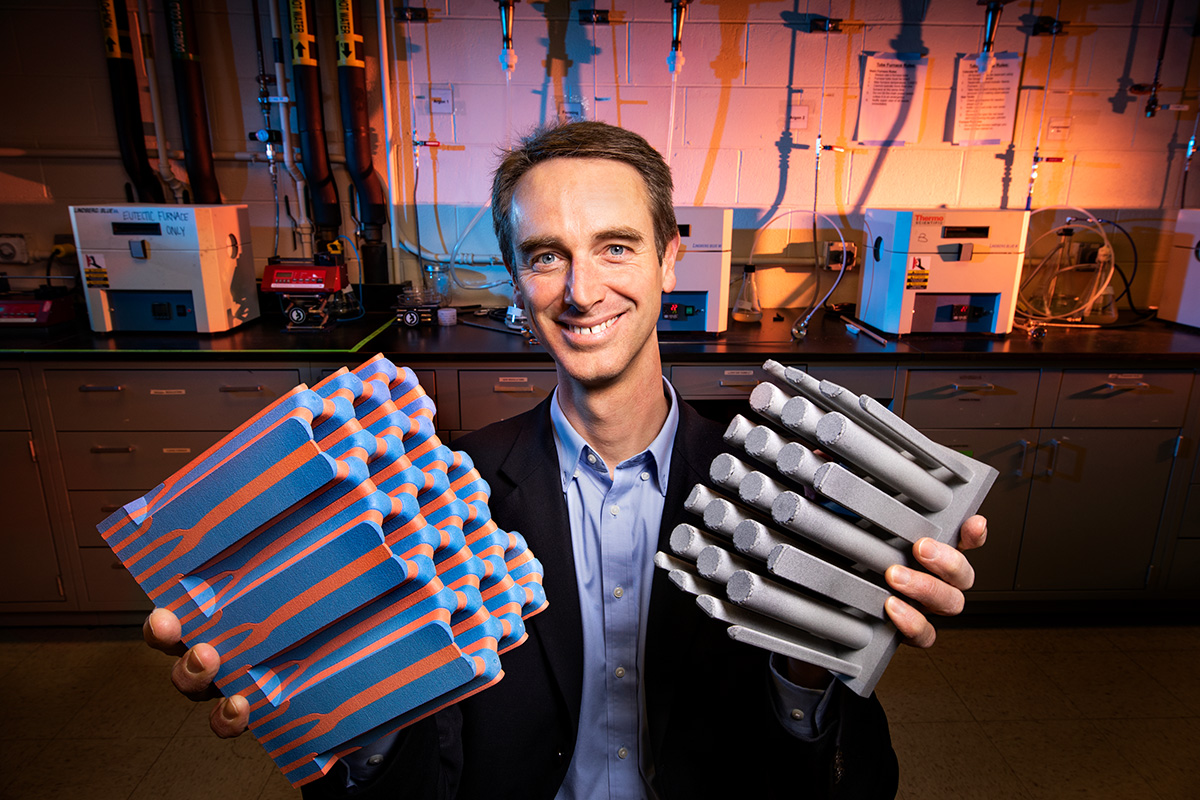

Paul Braun. Credit: Fred Zwicky, University of Illinois News Bureau.

“It was a great pleasure to work with Beckman to help define the configuration of the Versa to enable it to create new research opportunities for groups not just at Beckman and MRL, but in departments across our campus and even beyond it,” said Braun, who is also a professor and the W. W. Grainger Chair in Materials Science and Engineering.

Paul Braun. Credit: Fred Zwicky, University of Illinois News Bureau.

“It was a great pleasure to work with Beckman to help define the configuration of the Versa to enable it to create new research opportunities for groups not just at Beckman and MRL, but in departments across our campus and even beyond it,” said Braun, who is also a professor and the W. W. Grainger Chair in Materials Science and Engineering.

In addition to the Beckman Institute and the Materials Research Laboratory, The Grainger College of Engineering and Office for the Vice Chancellor of Research and Innovation committed funds to support purchasing the Versa 630.

The Beckman Microscopy Suite team is focused on finding projects on campus and beyond that might benefit from the Versa 630 and are providing comprehensive trainings for those new to the technology. Carl Zeiss Microscopy, the scanner’s manufacturer, is integral to these efforts.

"We at ZEISS are thrilled to be partnering with the Beckman Institute Microscopy Suite to deliver this flexible and intuitive system for X-ray microscopy," said Aubrey Funke, Carl Zeiss Microscopy Product Marketing Manager for Life Science EM/XRM. "The ability to image your sample, be it organic or material, becomes a less intimidating process on the ZEISS Xradia Versa 630. With high powered-resolution and expanded ease-of-use for all skill levels, the Versa 630 is ideal for diverse research capabilities across a spectrum of applications, including life science, electronics, materials research, and many more. We look forward to working with the Beckman Institute Microscopy Suite to support many diverse research projects.”

Beckman’s is the first 630 model for life science applications in the U.S.

First and foremost an entomologist, microscopist Gibson anticipates scanning more insect specimens.

“I am working with the paleontology lab at the Illinois Natural History Survey to CT-scan fossilized insects in amber — think the mosquitos from Jurassic Park,” he said.

As far as what the future holds for the Versa, Gibson said: “I personally do not know, but whatever it has in store I am excited for it!”

Excited, or scintillated?

Media contact: Jenna Kurtzweil, kurtzwe2@illinois.edu

Beckman Institute for Advanced Science and Technology