Autonomous Materials Systems Group

Transforming the entire life cycle of polymers and composites

Nature inspires the AMS group to change the world with better materials for sustainability, safety, aging and energy. Polymers and composites possess the necessary chemical and mechanical properties critical for achieving lightweight, durable structures in the energy (wind turbine blades), aerospace (aircraft and drones), and transportation industries (electric vehicles and trains)

However, the vast energy input required for initial manufacture, long cure times to develop desired structural properties and lack of end-of-life strategies render these materials unsustainable.

Transforming the entire life cycle of polymers and composites

Nature inspires the AMS group to change the world with better materials for sustainability, safety, aging and energy. Polymers and composites possess the necessary chemical and mechanical properties critical for achieving lightweight, durable structures in the energy (wind turbine blades), aerospace (aircraft and drones), and transportation industries (electric vehicles and trains)

However, the vast energy input required for initial manufacture, long cure times to develop desired structural properties and lack of end-of-life strategies render these materials unsustainable.

Motivated by living systems’ continuous growth, regeneration and repair, this interdisciplinary team of chemists, materials scientists and engineers is focused on developing fast, efficient manufacturing methods, extending service life through self-healing and building in regenerative end-of-life strategies to enable recycling.

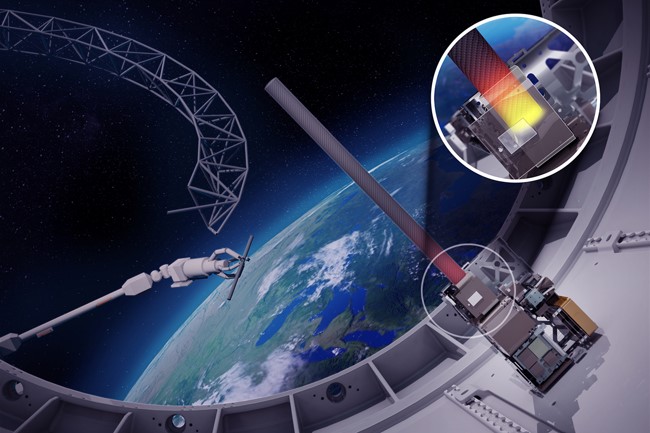

The AMS group is sending its research to space. Mission Illinois will demonstrate the first ever on-orbit manufacturing of composite materials. The team will send a tool designed and built at Beckman, similar to a large 3D printer, to space that will produce large, high stiffness composite tubes. These tools and materials could eventually enable manufacture large space structures, including space telescopes and antennas.

The AMS group is sending its research to space. Mission Illinois will demonstrate the first ever on-orbit manufacturing of composite materials. The team will send a tool designed and built at Beckman, similar to a large 3D printer, to space that will produce large, high stiffness composite tubes. These tools and materials could eventually enable manufacture large space structures, including space telescopes and antennas.

Group leaders

- Nancy R. Sottos

- Sameh Tawfick

Labs within this group

- The Baur Group

- Braun Research Group

- Diao Research Group

- Ewoldt Research Group

- Kinetic Materials Research Group

- The Moore Group

- Sottos Group

- Researchers develop in-space manufacturing through new research center

- From 2D to 3D: Beckman researchers develop method for manufacturing large structures in space

- Beckman researchers discover spontaneous chirality in conjugated polymers

- Beckman researchers turn carbon-fiber recycling waste into useful materials

- Inspired by nature: Beckman researchers receive $2M grant to develop chiral electronics

- Varda Hagh joins Beckman faculty

Beckman Institute for Advanced Science and Technology